Aciturri Hystorage is born from Aciturri, a benchmark in the aerospace sector and recognized as a leading supplier of aerostructures and engine components for the world’s top aircraft manufacturers, with more than 3.000 employees and 16 manufacturing plants around the word. Leveraging over 30 years of experience in the design and manufacture of complex carbon fiber structures, Aciturri has built a reputation for excellence in high-performance composite technologies.

In 2021, Aciturri launched a strategic R&D program focused on the development of Type IV compressed hydrogen tanks, specifically targeting heavy-duty road mobility. After four years of development, Aciturri achieved an innovative, high-quality, and cost-competitive hydrogen tank, setting a new benchmark in the market.

To capitalize on this technological breakthrough and to support the growth of sustainable mobility, Aciturri created Aciturri Hystorage, focused on the design, manufacture, and commercialization of advanced hydrogen storage systems. Our solutions address two key markets: On-road mobility for hydrogen-powered heavy-duty vehicles and hydrogen distribution through high-capacity Multi-Element Gas Containers (MEGCs).

Our value proposition is straightforward: delivering the lowest total cost of ownership (TCO) in the hydrogen distribution market, while ensuring the highest quality and safety standards inherited from our aerospace DNA.

Aciturri HyStorage has developed an innovative, robust and flexible Type 4 composite pressure cylinder technology that can be applied to a wide range of mobility, transportation and storage solutions in the hydrogen industry. Our Hydrogen Cylinders have a nominal working pressures of 350 bar and 500 bar for stationary storage and transportation, and 350 bar and 700 bar for mobility applications.

Our Type 4 composite (CFRP) pressure vessels made with towpreg filament winding technology offer significant advantages over other pressure vessels:

Aciturri has extensive experience in reducing the weight of carbon fiber components for the aerospace industry, with over 30 years of expertise in designing and manufacturing this type of components. This expertise enables us to achieve gravimetric efficiencies ranging from 7% to 8%, depending on the tank configuration.

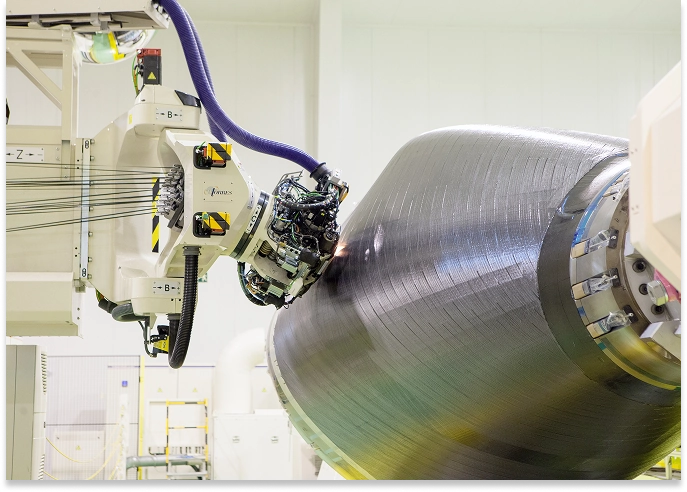

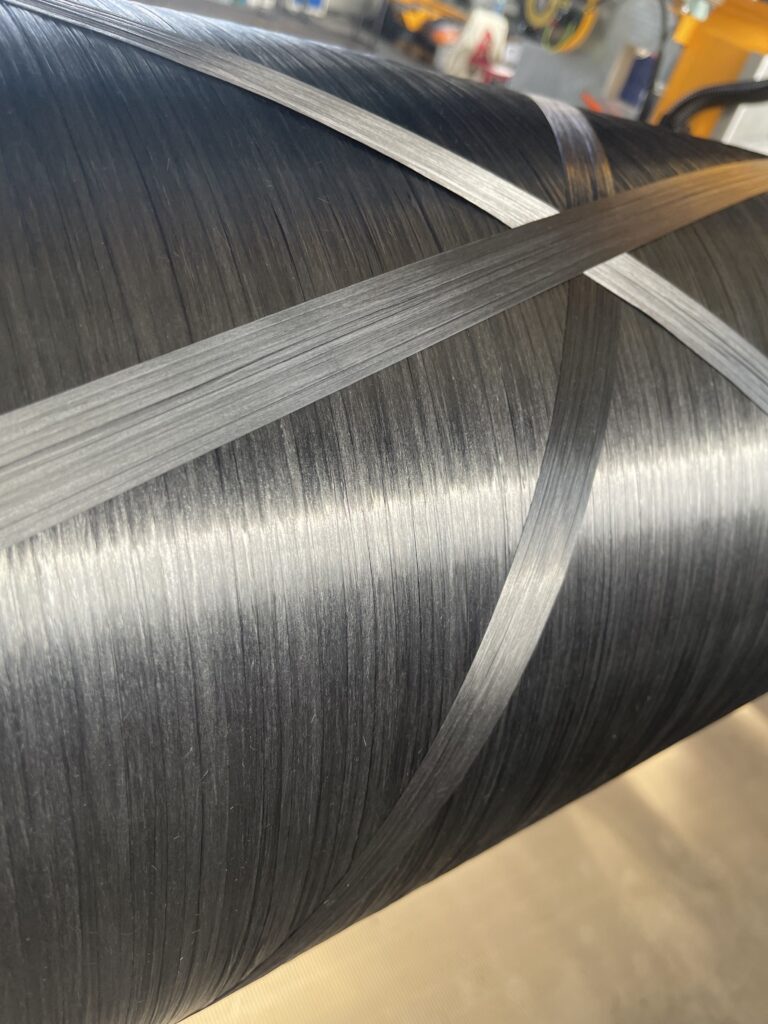

We manufacture our type 4 tanks using towpreg material, a pre-impregnated carbon fiber material that allows us to reduce the weight of the tank by around 15% compared to the traditional wet-winding process employed in the industry, thanks to the higher quality achieved with this material.

Our strategy focuses on the internalization of key manufacturing processes, including liner manufacturing, tank towpreg winding and hydraulic testing. This high level of vertical integration ensures strong cost control and supports a lean manufacturing approach, leading to significant cost savings and enabling a unique price-to-performance ratio in the market.

We manufacture our own aerospace-grade towpreg material with the objective of bridging the cost differential between dry fibers and the towpreg material.

The use of towpreg material enables high precision in tows placement and better control of the resin content, resulting in significantly lower defects rates and scrap ratios thanks to the high repeatability of the process.

The non-quality costs are comparable to those of other pre-preg manufacturing processes used in aerospace part production, being up to five times lower than those associated with the traditional wet-winding process, which is a much more variable process.

The higher precision and repeatability lead to higher safety standards

The liner material is a specifically developed Polyamide designed for hydrogen tank applications, offering much lower permeability than other commonly used materials on the market.

All hydrogen pressure vessels from ACITURRI undergo intensive testing. Our pressure vessels fulfil all industrial certification requirements according to the following industrial standards:

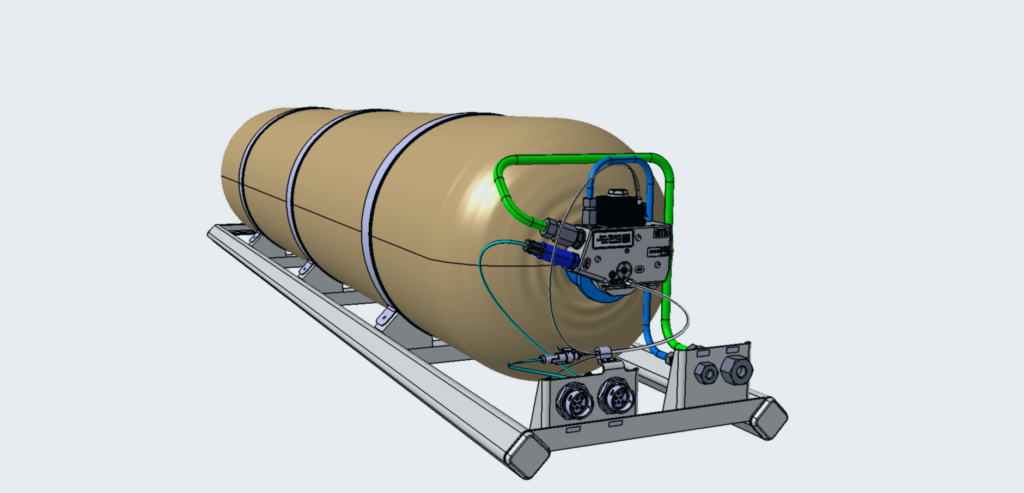

Aciturri Hystorage provides multiple element gas containers (MEGC) for different pressure levels and storage capacity based on our high-strength, lightweight composite Type 4 tanks for hydrogen distribution and storage.

We offer a flexible modular solution to distribute hydrogen from the producer to the consumer, fully adaptable to the specific transport operational requirements of each customer. Our hydrogen distribution modules are based on standardized container designed for seamless multimodal transport across road, rail, and sea.

Our hydrogen distribution modules have an unlimited service life with periodic inspections.

Our mobile storage systems are based on Type-4 tanks, manufactured by towpreg filament winding technology and tested according to EN 17339. These transportations modules are approved according to TPED & ADR for transportation and PED for stationary storage.

Our transportation and storage modules are designed for nominal working pressures of 350 bar and 500 bar. These hydrogen modules are built using standardized container sizes of 10ft, 20ft, 30ft, and 40ft. At 500 bar, the 40ft container provides a maximum hydrogen capacity of over 1.1 tons—three to four times greater than that of a conventional metallic tube trailer.

Hydrogen storage systems provide a zero-emission energy source for heavy-duty transportation, especially for bus fleets and long-haul trucks. Releasing nothing but water vapor in operation, hydrogen offers a sustainable alternative to fossil fuels and plays a key role in driving down emissions across the transport sector.

Aciturri HyStorage provides high pressure hydrogen storage systems based on Type-4 cylinders for use in heavy duty vehicles, from transit buses to long-haul trucks. We supply a fully integrated system from the fuel inlet to the fuel cell inlet, incorporating R134-certified valves, pressure regulators, and piping. Each unit is leak- and function-tested prior to delivery and includes a Storage System Control Unit that monitors the refueling process while ensuring the safety and efficiency of the storage system.

Featuring a modular and flexible plug & drive concept, The system allows for quick and effortless integration and assembly, supported by an easy and quick anchorage system.

The hydrogen storage system is based on type-IV cylinders produced with towpreg filament winding technology, ensuring the highest quality and safety standards, certified according to UNECE R134.

Thanks to the Polyamide liner’s high maximum operating temperature, combined with thermodynamic optimization, the system enables refueling times of under 10 minutes.

We adapt to customer needs: Our system allows for customization and co-development with the customer to facilitate integration with their equipment.

For over 30 years, Aciturri’s engineering team has been at the forefront of designing and manufacturing advanced carbon fiber components for the aerospace industry. Our clients trust us for our cutting-edge technology and the exceptional quality that define every product we deliver. We cover the entire product lifecycle — from design, stress analysis, and systems development to mass production, certification, and after-sales technical support

At Aciturri HyStorage, we manage the entire production process in-house, ensuring unmatched quality, efficiency, and reliability. From manufacturing our own Tow-Preg materials to advanced Filament Winding and Rotomoulding technologies, every step is optimized for performance and cost-effectiveness .Our in-house hydraulic test facilities allow us to carry out rigorous Burst, Proof and Drop & Flawed Cylinder tests, guaranteeing that every component meets the highest standards. Finally, our Systems Assembly Area ensures precise integration and readiness for delivery.

Aciturri HyStorage invested in a new hydrogen type-4 cylinder manufacturing and systems assembly facility located in Seville (Spain) to provide capacity to meet the rapidly growing demand for mobility and infrastructure applications. This new plant is built on lean manufacturing principles, featuring a flexible, high-tech layout that enables continuous flow, minimal inventory, and rapid scalability. Designed for efficiency, safety, and adaptability, it’s a benchmark in advanced type-4 hydrogen cylinder production.